Welcome to the June 23, 2023 issue of Cotton News, a service provided by Plains Cotton Growers Inc. for the cotton industry in the Texas High Plains and beyond.

Dryland field in Petersburg, Texas (Hale County).

Texas High Plains Crop Conditions — Need Another Rain

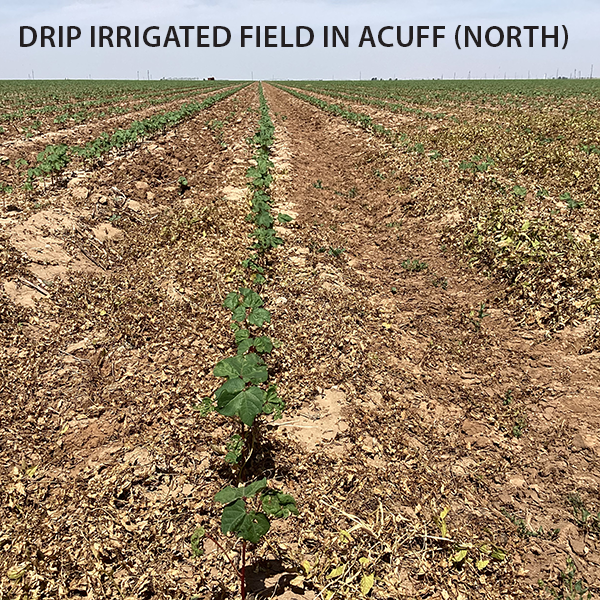

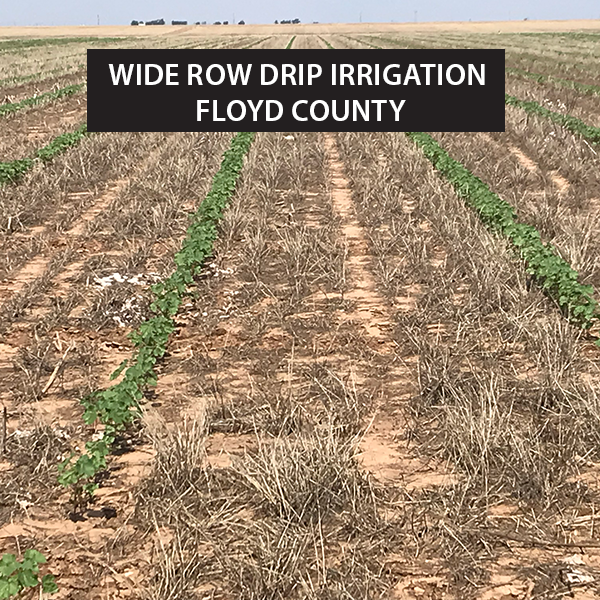

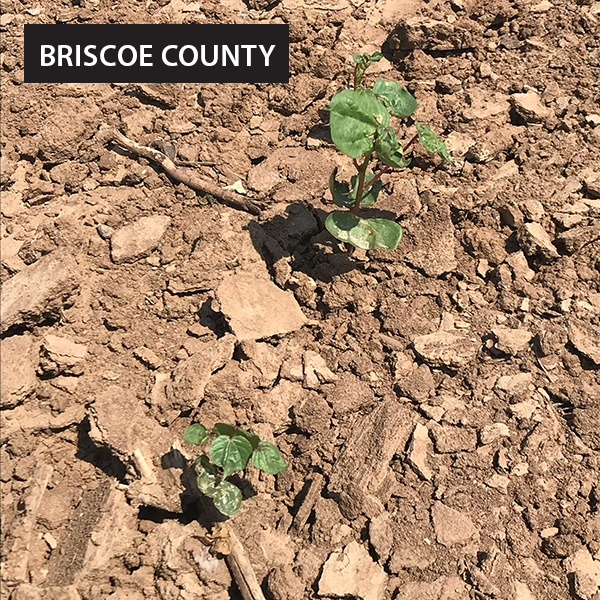

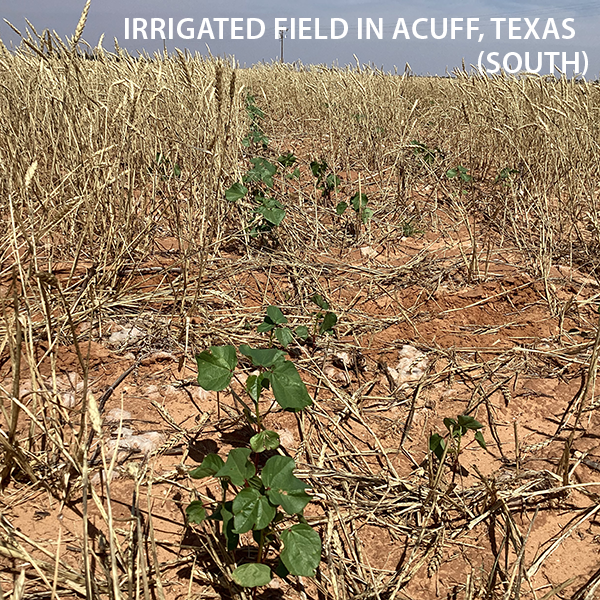

Mid-May, PCG’s reporting focused primarily on the necessity of drought relief. By the end of May, fields in certain areas of PCG’s 42 counties were flooding and planting was delayed. On June 9,

2023, we were concerned about heat units and the need for warmer temperatures. We saw temperatures come up to the high 90s for most of June 12 through the 16th. Now, with established stands and some squaring observations, we could use another rain.

And we may just get one, if historical data is anything to go by. According to historical rain data for Lubbock, anytime May has recorded five or more inches of rain, there has typically been good precipitation through June and the rest of the growing season. Hopefully that will be the case this crop year.

The cotton that did emerge and was not damaged by weather conditions has looked pretty good. “We have seen more uniform stands this year than we have in the past,” added Kody Bessent, PCG CEO.

According to PCG Director of Field Services Mark Brown, the crop north of Plainview is suffering. Large storms, hail and tornadoes have hit the region hard. “We lost 1,400 more acres of cotton right after the Perryton tornado,” said Quentin Shieldknight, producer in Hansford County.

Brown added that east of Lubbock, the situation is better. In his spot checks, Brown said he has seen cotton all over the board in terms of growth and development — from emergence to one true leaf all the way up to match-head squares. “If a producer has match-head squares in their field today, it’s more than likely they’ll have blooms by the July 15, which is pretty typical in a normal growing season,” Brown added.

Pest Management Report

While rain is always welcome, it does increase the insect pressure. Experts report thrip and grasshopper activity in fields, but what is most concerning are wireworms. Wireworms can be hard to find when scouting and can be hard to treat after the cotton has emerged.

find when scouting and can be hard to treat after the cotton has emerged.

“We have product options with grasshoppers, fleahoppers and thrips, but once you plant, there’s nothing you can do to prevent wireworms,” said Suhas Vyavhare, Ph.D., extension entomologist.

Shawn Holladay, producer in Dawson and Marting Counties said he’s seen more wireworms this year than he’s ever seen before.

“We’ve learned a valuable lesson this year,” he added. “We won’t plant irrigated cotton that’s not seed treated again.”

Vyavhare also said to be on the lookout for plant bugs now that plants are beginning to square.

Hale County Goes to Amsterdam

Steve Olson, producer in Hale County, served as a panelist discussing regenerative agriculture at a cotton conference overseas.

“One thing that really stands out to me in these global experiences is how fortunate we are here in America,” Olson said. “There was a panelist from India that talked about the ability to finally purchase oxen to help him on the farm. There was also a woman discussing using her farm profits to put her children through school. It’s humbling to think about.”

Intern Perspective

Riley Gryder and Josiah Keck were named Texas Cotton Ginners’ Association summer interns in May.

By the end of the summer, Gryder will have worked with Adobe Walls Gin, Edcot Gin, Johnson Gin, LoneStar Gin and Top of Texas Gin.

Keck is working with Petersburg Co-op Gin and will finish his internship at Smith Gin Co-op in South Texas.

Intern Story: Gryder

Riley Gryder

Originally published in TCGA’s “The Ginnery” newsletter.

With my first month as a TCGA intern coming to an end, I am proud to say that I have learned far more than I expected to. Assigned to Phillip Kidd at Edcot Gin in Edmonson, Texas, I have traveled around the Panhandle working alongside many great people such as Landon Kidd, Daniel Jenkins, Steven Birkenfeld, and Malcom Jones. Learning the ins and outs of ginning, I have toured and worked at three Windstar gins – Edcot Gin, Johnson Gin, and Top of Texas Gin.

traveled around the Panhandle working alongside many great people such as Landon Kidd, Daniel Jenkins, Steven Birkenfeld, and Malcom Jones. Learning the ins and outs of ginning, I have toured and worked at three Windstar gins – Edcot Gin, Johnson Gin, and Top of Texas Gin.

My internship began with an extensive, hands-on tour of Edcot gin led by Landon Kidd. Throughout the week, I had the opportunity to learn about trading seed, lint, and even got to tour BC Supply and MTS in Lubbock. The second week, I stayed in Turkey, Texas with a great host and manager – Daniel Jenkins. While traveling back and forth to the Johnson Gin in Silverton, I got to see how the caprock affects cotton growers in the area. With entirely different planting dates, it looks like this area might have a higher yield of cotton compared to the Caprock, which has had a tough season.

While at the Johnson Gin, I had the opportunity to work with Kevin Williams and learn what happens inside of gins to keep them running. Pulling wires and putting in new control panels was our main focus here at Johnson Gin, as well as Top of Texas Gin. Working under Malcom Jones, I was tasked to shadow a group of skilled electricians as we installed new module feeder and shaft monitoring control systems. While the job isn’t done, I plan to revisit Top of Texas Gin in the coming weeks, along with Adobe Walls Gin and Lonestar Gin in Pampa, Texas. Overall, I have had many great experiences with many great people. I have learned more in two weeks than most get to learn in a lifetime. I would like to thank Aaron Nelsen for giving me this opportunity and Phillip Kidd for organizing and allowing me to have these great opportunities. I cannot wait to learn more about cotton growing and ginning all over Texas.

Gryder is a mechanical engineering student at Texas Tech University.

Intern Story: Keck

Josiah Keck

Originally published in TCGA’s “The Ginnery” newsletter.

I have been working for Myles Ramsey, manager of Petersburg CO-OP Gin, for the first half of my internship. I have been learning the process of cotton ginning from Mr. Ramsey. The first week I helped take apart augers in the distributor. Next, I took apart the hangers which are attached to the augers. I cleaned and replaced chains around the sprockets and checked for any damage around the drive shaft, sprocket, and ball bearings. Later that same week, I helped one of my co-workers clean out and replace the gin stand saws. Mr. Ramsey also took me on several tours. We toured PYCO, RAM Manufacturing, and where the cotton samples go to be graded. PYCO was one of the most fascinating to me. PYCO is where the cotton seed, after being ginned, goes to be made into cottonseed oil. There I learned about the process of how a cotton seed is turned into oil. What was very fascinating to me was the lint around the cotton seed. PYCO has three cleaning processes of taking the lint off the seed, they later turn the lint into bales. One of the coolest facts I learned from the lint is that Samsung buys some of this lint to make their devices. During my time at Petersburg Cotton Gin, I have been asking lots of questions about the sales side of cotton. I talked to one of the PCCA workers and learned about the pool and grades of cotton. PCCA buys portions of cotton to add to their pool. The pool helps get more leverage in the cotton market.

The first part of my internship was a blast! I have learned a lot from Mr. Ramsey, and I appreciated the time he has put into teaching me the ins and outs of the cotton gin. In the second part of my internship, I will be working for Smith Gin Co-op in Odem Texas. I am very excited to also get to see how the gins are run during the season.

Keck is an agricultural systems management student at Texas A&M University.